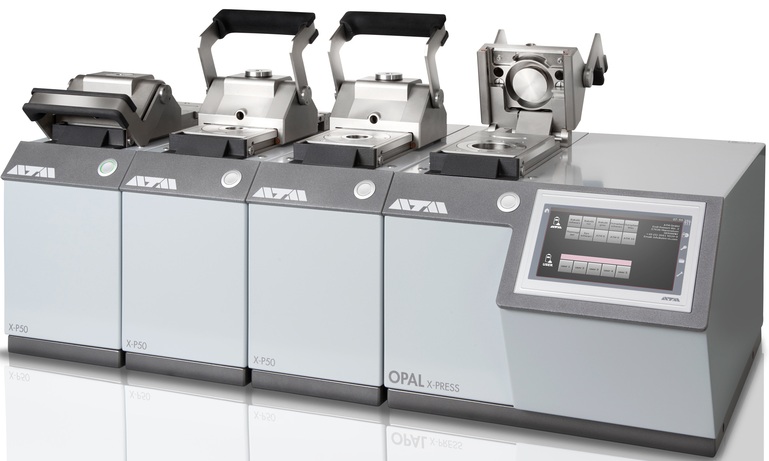

Modular Hot Mounting Press Machine OPAL-XPRESS

Model: OPAL XPRESS

Manufacturer: ATM Qness GmbH - Germany

Home > Hot Mounting Press Machines

The Opal X-Press is a modular hot mounting press for fast and simultaneous, independent mounting of different materialographic specimens. The modularity of the Opal X-Press allows for optimum configuration for different sample sizes according to customer requirements.

The basic device contains the control interface and one mold assembly. It is available in 2 versions:

- Opal X-Press 2: can be equipped with one additional pressing units (total up to 2 pressing units)

- Opal X-Press 4: can be equipped with up to three additional pressing units (total up to 4 pressing units)

The pressing units are separated from the basic device and may be added later. Thus it is possible to generate samples of up to 2 (Opal X-Press 2) respectively 4 (Opal X-Pess 4) different diameters simultaneously in one device. The diameter of the pressing unit - each with or without chamfer - can be selected between 25.2 mm, 30 mm, 1¼" (~32 mm), 1½" (~38 mm), 40 mm, 50 mm.

The integrated dust extractor Dust Guard protects the operator from inhaling fine dust, which is released when filling the mounting material. The external vacuum cleaner is controlled via the user interface of the basic unit.

The intuitive control software with a 7" touch screen features pre-installed mounting methods and consumables, plus the possibility to store more than 200 user-defined programs. Various user accounts with different access rights can be created to set user restrictions and define custom maintenance tasks as well as cooling modes. The operator can be equipped with different access privileges, e. g. to edit parameters and define custom maintenance tasks as well as cooling modes if needed.

The Opal X-Press is designed for fast mounting including a user definable pre-heat function and safes significantly time compared to other hot mounting presses.

The proven one-hand closure system has been further developed and transports excess mounting material into the integrated dirt trap when the mold is closed. Dust is removed through the suction nozzle during filling. The closure of the mold can be raised for easy cleaning of the upper ram.

The modern design of the powder-coated steel housing and the high-quality components make the hot mounting press Opal X-Press a robust device with a small footprint. Minimum power consumption with maximum configuration options ensures impressive efficiency.

PRODUCT ADVANTAGES

- Modular hot mounting press

- Opal X-Press 2: basic unit extendable with 1 additional pressing unit

- Opal X-Press 4: basic unit extendable with up to 3 additional pressing units

- Fast mounting with low power consumption

- Proven one-hand closure system with integrated dirt trap and suction nozzle

- Dust Guard: removal of fine dust during filling of mold by connected vacuum cleaner

- 7" touch display with innovative control software

- High flexibility due to preheating function, cooling modes, maintenance tasks and user accounts with different access rights

FEATURES

| Modular design | |

| Max. number of pressing units | 2/4 Opal X-Press 2: up to 2 Opal X-Press 4: up to 4 |

| Mould assembly | Ø 25.2 - 50 mm (6 different sizes) |

| Closure system | slide closure |

| Thermostate range | 20-200°C |

| Heating time | adjustable |

| Cooling time | adjustable |

| Max. pressure in mould assembly depending on mould assembly's size | 250-350 bar |

| Connection power (basic unit) | 1.6 kVA |

| Connection power (additional pressing unit) | 1.5 kVA |

| Heating power | 1200 W |

| W x H x D (basic unit) | 402 x 382 x 563 mm |

| W x H x D (additional pressing unit) | 187 x 382 x 449 mm |

| Weight | ~ 50 kg |