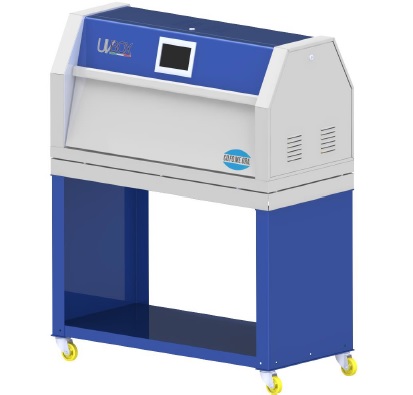

UV BOX COFOMEGRA (UVA, UVB)

Maker: Cofomegra - Italia

The UV accelerated aging test reproduces the damage caused by sunlight, rain and dew. In a few days or weeks of exposure of samples inside the UV BOX you can reproduce the damage that takes place in months or years of exposure outside.

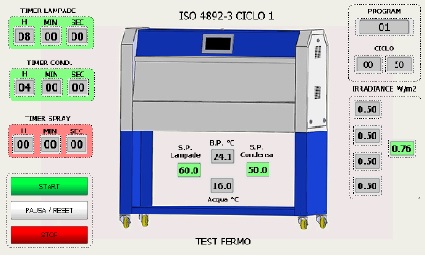

To simulate aging due to external weather, UV BOX subjects materials to alternating cycles of UV radiation and humidity at controlled high temperatures. The instrument simulates the effects of sunlight through the use of special UV fluorescent lamps and the simulation of the dew effect and rain takes place through condensation or a water spray (Spray option). UV radiation is responsible for almost all photodegradation processes of durable materials exposed to the external environment. The fluorescent lamps used in UV BOX simulate critical UV short waves and realistically reproduce the damage caused by sunlight. The types of damage that can be simulated with UV BOX are as follows: color change, loss of brilliance, cleavage, cracks, cracks, blisters, veiling, fragility, loss of robustness and oxidation.

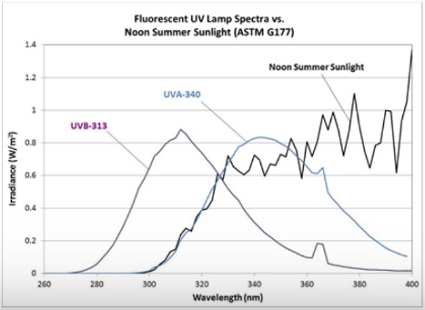

UV lamps

UV fluorescent lamps are more stable than other types of lamps and offer the best UV simulation of the sun. The spectral distribution (SPD) is not modified with the aging of the lamp, even after thousands of hours of operation, and this feature results more reproducible results, lower frequency of lamp replacements and a reduction in operating costs.

UVA-340 lamps

Uva-340 lamps provide the best simulation of sunlight in the critical wavelength region from 365 nm up to the cut-off solar value of 295 nm.

UVB-313 lamps

UVB-313 lamps maximize acceleration through the use of more aggressive UV short waves than those that normally arrive on the Earth's surface. As a result, for some materials these lamps may produce too severe results.

Why buy UV BOX COFOMEGRA?

- New Italian design very functional.

- Automatic restart after power outage.

- Portable samples for 3D samples or customer-requested sizes. Standard sample holder for 48 samples.

- Touchscreen control with pre-programmed standards and free programming testing.

- Advanced calibration technology.

- Consistent radiation and temperature distribution.

- Virtually maintenance-free.

- High industry competitiveness 4.0.

Technical Specifications:

|

ModelUVBOX–Enhanced |

|

|

Electricalrequirements |

|

|

Mainsvoltage |

230 Vac10%, 50/60Hz. |

|

Mainsconnection |

1/N/PE |

|

Currentconsumption |

10A (max.) |

|

Measures andweight |

|

|

Dimensions |

1300 x700 x1500mm. |

|

Weight |

120Kg. |

|

StandardSpecimen Capacity |

48 |

|

Features |

|

|

LampUV (UVA or UVB) |

8 |

|

Adjustment and control ofirradiance level |

yes |

|

Displayof currentirradiancelevel |

yes |

|

Irradiance: |

min0.35W/m²(UVA, UVB) –max1.55W/m²(UVA) - 1.23W/m²(UVB) |

|

BPTblack panel temperature range |

StageUV 35-80°C–stagecondensation35-60°C |

|

Microprocessorcontrol |

yes |

|

Controlpanel touch screen |

yes |

|

Test report |

yes |

|

Storingvarioustestconditions,free programmingof testsstandards |

yes |

|

Calibrationsensorprogram |

yes |

|

Connectivity |

Ethernet yes – WiFi optional |

|

Water for condensation stage |

Pressure2-3 bar–water demineralized recommended |

|

Water for spraystage (optional) |

Pressure 2-6 bar– conductivity<5µS/cm |

|

Standard |

ASTMD4329, D4587, D4799,D5208,D6662,G53,G154,G151 ISO 4892-3, 11507,11895,11997-2 EN 927-6,1297, 12224, 13523-10, 1898, pr 1062-4SAE J2020–AATCC TM186 |