Fully Automatic Micro Hardness Tester

Manufacturer: ATM Qness GmbH - Germany

Origin: Austria

Home > Hardness testing machines

TEST METHODS AND FORCE APPLICATION:

Q10A/A+: 50g - 10kg

Q30A/A+: 100g - 31.25kg

Q60A/A+: 200g - 62.5kg

Vickers

DIN EN ISO 6507, ASTM E-384, ASTM E92

HV 0.00025, HV 0.0005, HV 0.001, HV 0.002, HV 0.005, HV 0.01, HV 0.02, HV 0.025, HV 0.05, HV 0.1, HV 0.2, HV 0.3, HV 0.5, HV 1, HV 2, HV 3, HV 5, HV 10, HV 20, HV 30, HV 50, HV 60

Knoop

DIN EN ISO 4545, ASTM E-384, ASTM E92

HK 0.00025, HK 0.0005, HK 0.001, HK 0.002, HK 0.003, HK 0.005, HK 0.01, HK 0.02, HK 0.025, HK 0.05, HK 0.1, HK 0.2, HK 0.3, HK 0.5, HK 1, HK 2

Brinell

DIN EN ISO 6506, ASTM E-10

HBW 1/1, HBW 1/2.5, HBW 1/5, HBW 1/10, HBW 1/30, HBW 2.5/31.25, HBW 2.5/62.5, HBW 5/62.5 (> 30 HBW)

Integrated conversions:

DIN EN ISO 18265, DIN EN ISO 50150, ASTM E-140

FULL AUTOMATION IN PERFECTION

LOAD SAMPLES, LOAD ROW, START --> 3 STEPS TO THE RESULT

1. LOAD SAMPLES

The machine moves automatically to sample holder height. Image of sample is taken automatically.

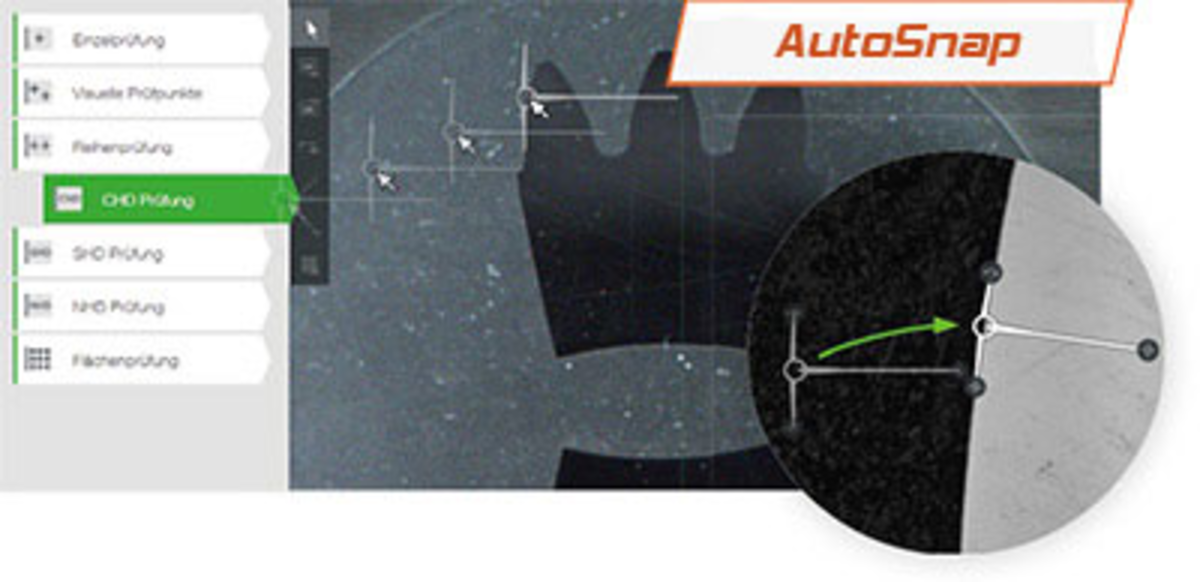

2. LOAD ROW

AutoSnap - Speedy Row Set-up: Drag the row of test points to the desired position. The serial Auto-Snap function corrects the starting point of the test row automatically.

3. START TEST SEQUENCE

The test sequence is executed according to the applicable hardness testing standards.

PRACTICAL APPLICATIONS

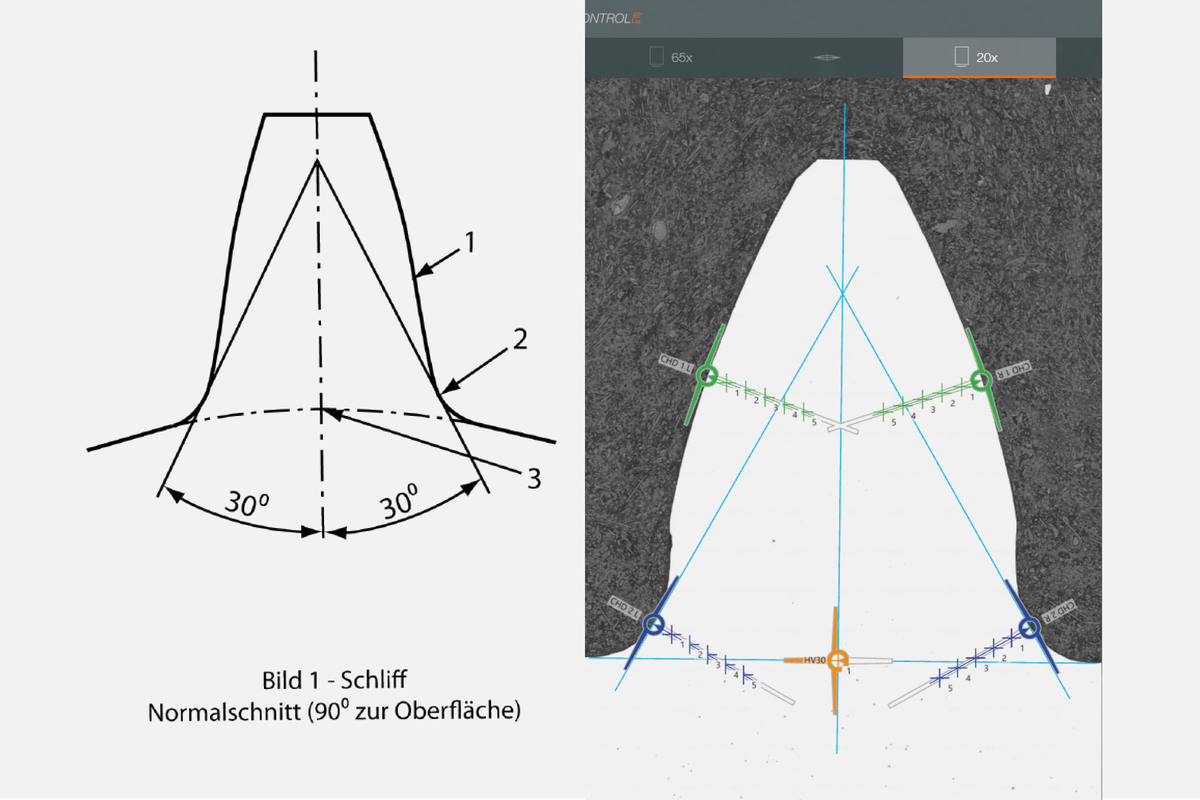

TOOTH FLANK TESTING

The time-consuming creation of test points, especially with tooth flank testing, is minimized by means of pre-defined test templates. With the Q30A+ the entire normed procedure between HV30 and HV0,5 can be done by one single device. Certainly a corresponding report is stored. The report can be adapted to customer specification.

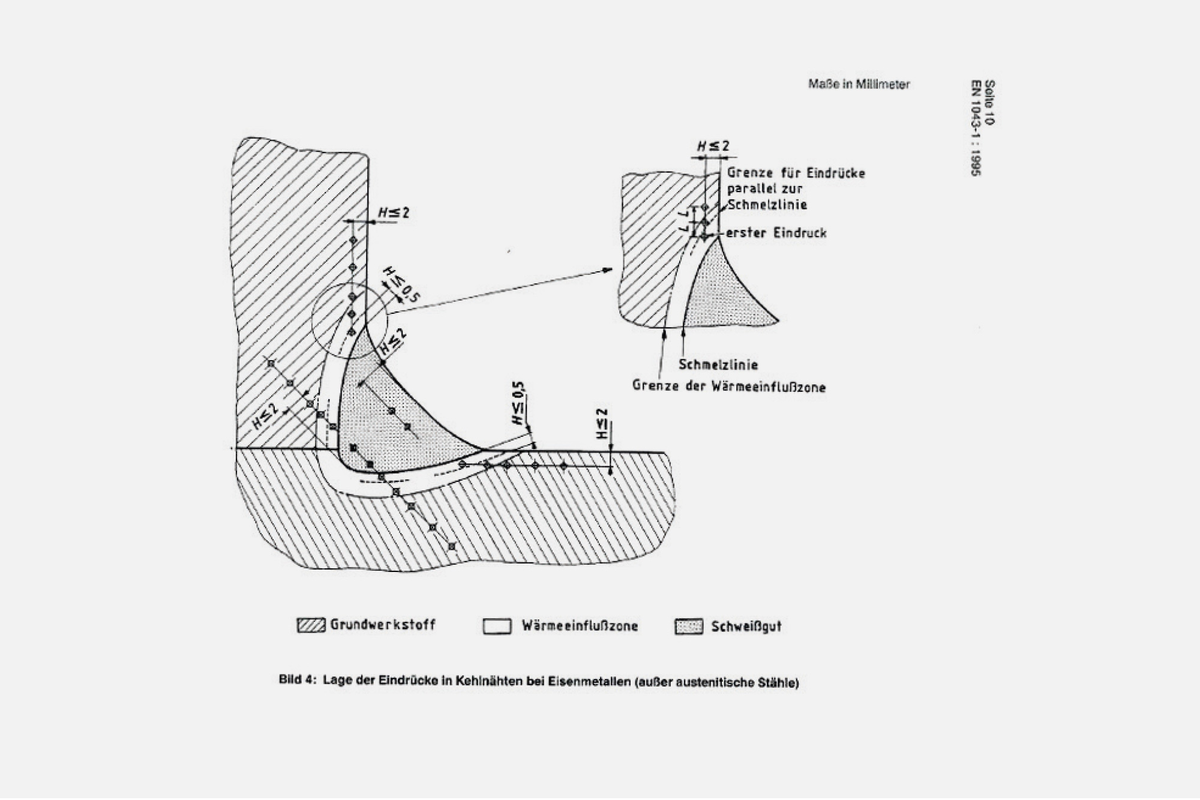

WELDING TEST SAMPLES

- Ideal for welding test samples or test point positioning jobs

- Test points can be positioned accurate based on the graphic design acc. to standard

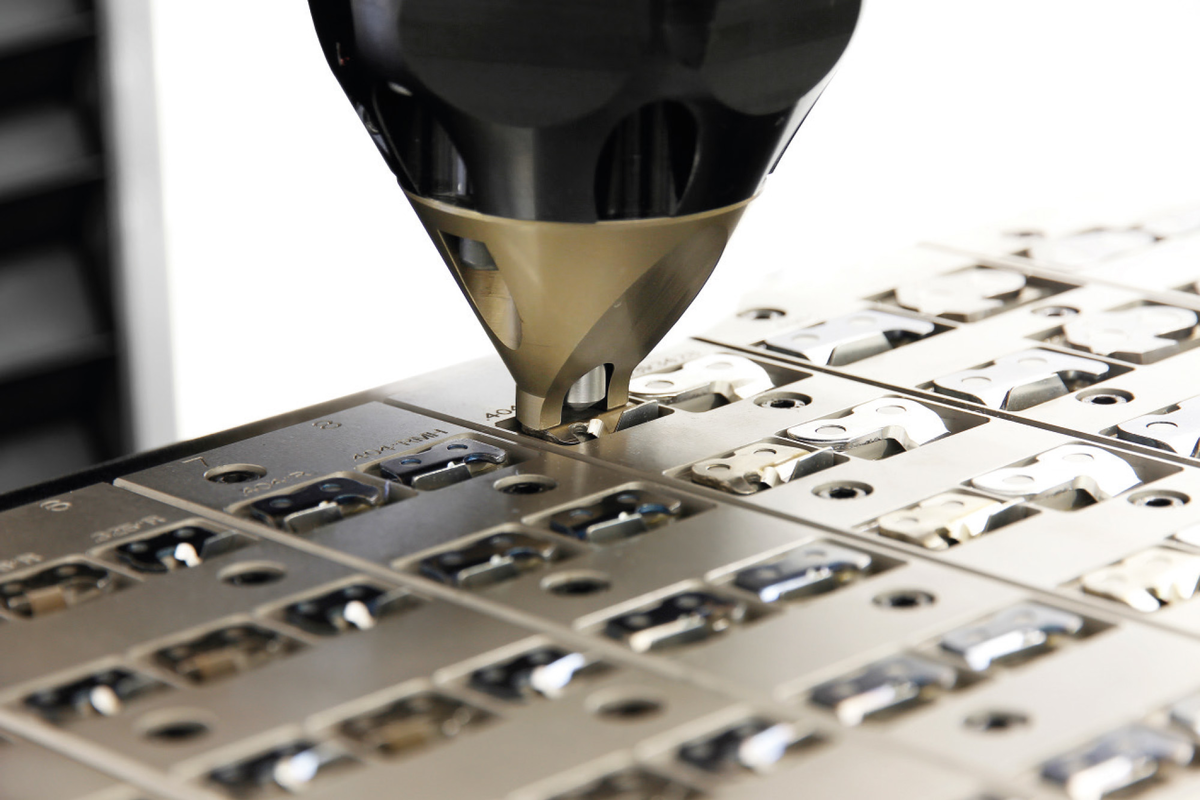

SAME PARTS TESTING

Recurring samples can be saved as a template. Using defined sample magazines all relevant data such as test samples, test method and user fields to be activated.

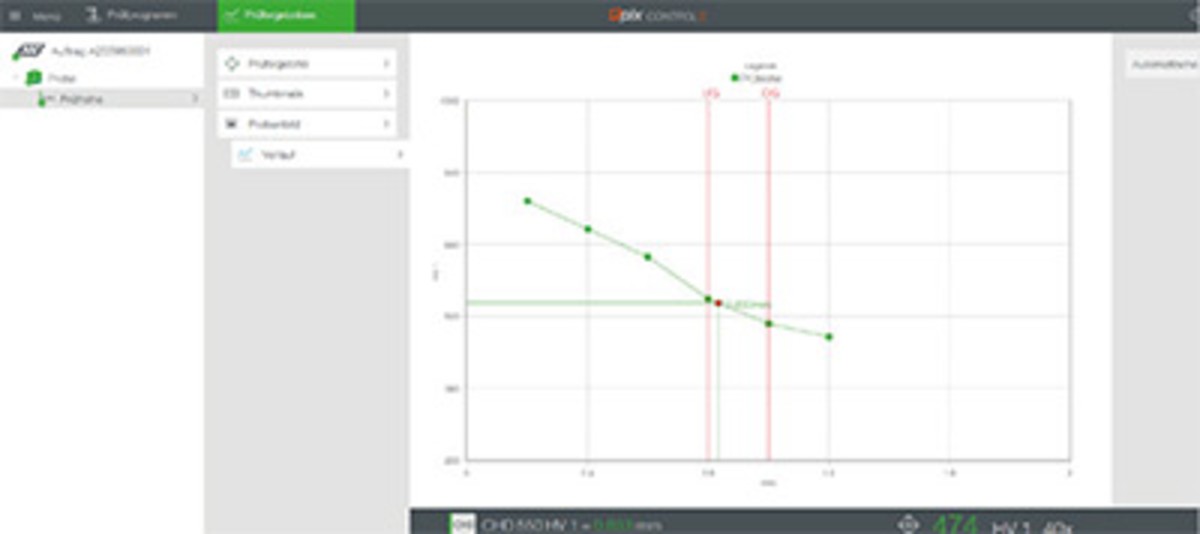

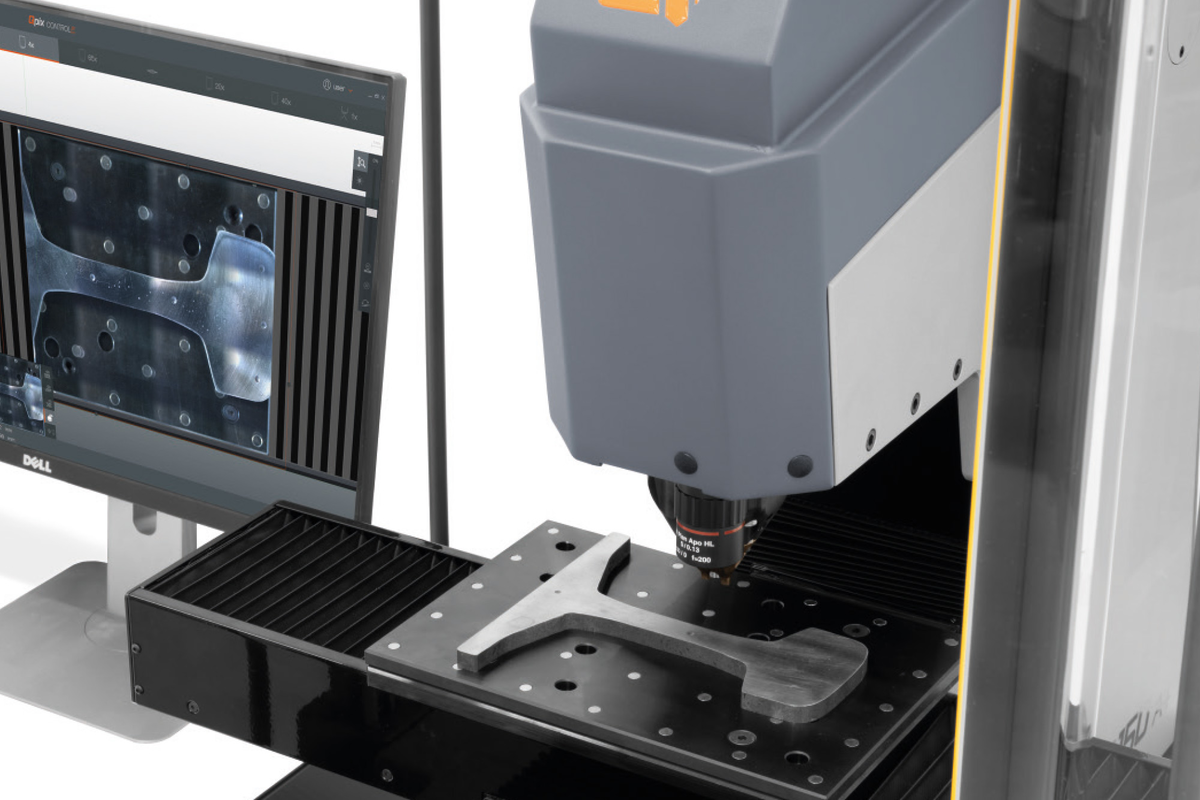

BEDDED SAMPLES FOR CHD, NHD, SHD

The sample patterns can be easily selected through the Program. In addition to the single and row measurement the user can select CHD, NHD and SHD.

RAIL TESTING

One application is to measure the testing of rail profiles. The complete track can be scanned via the standardized panorama function and thus allows an accurate and fast positioning of the individual test series at the same time.

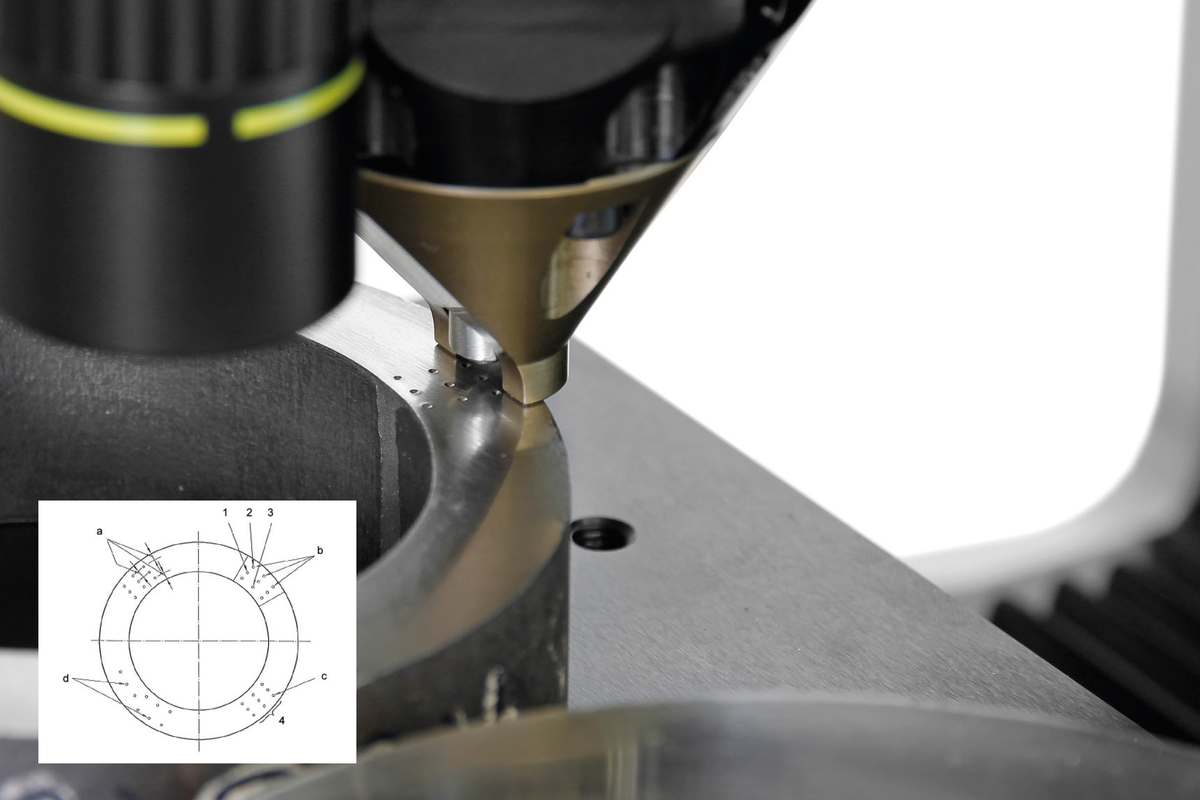

PIPE TESTING

With the Q10/Q30 A or A+, you can check your pipes economically according to the applicable API standards.

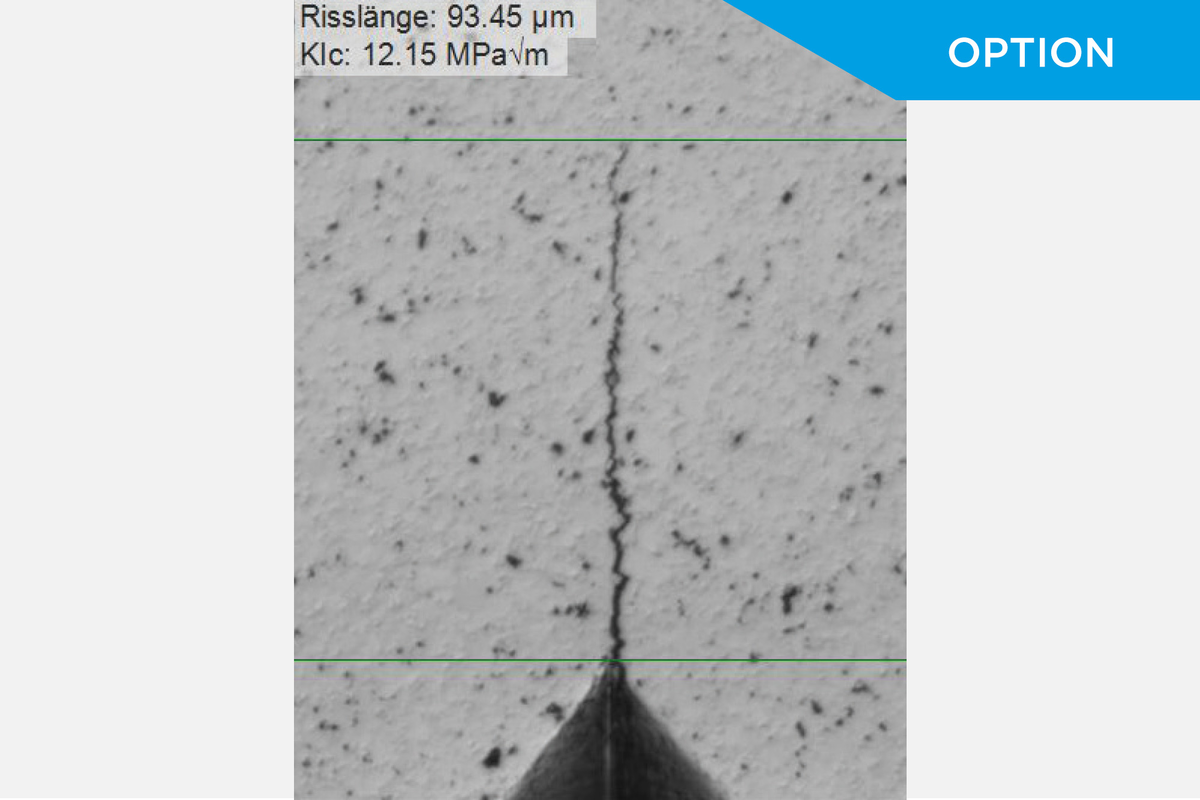

CRACK LENGTH MEASURING

For evaluating the K1C value the 4 cracks are measured according to the norm. After that the MPa√m value is evaluated automatically.

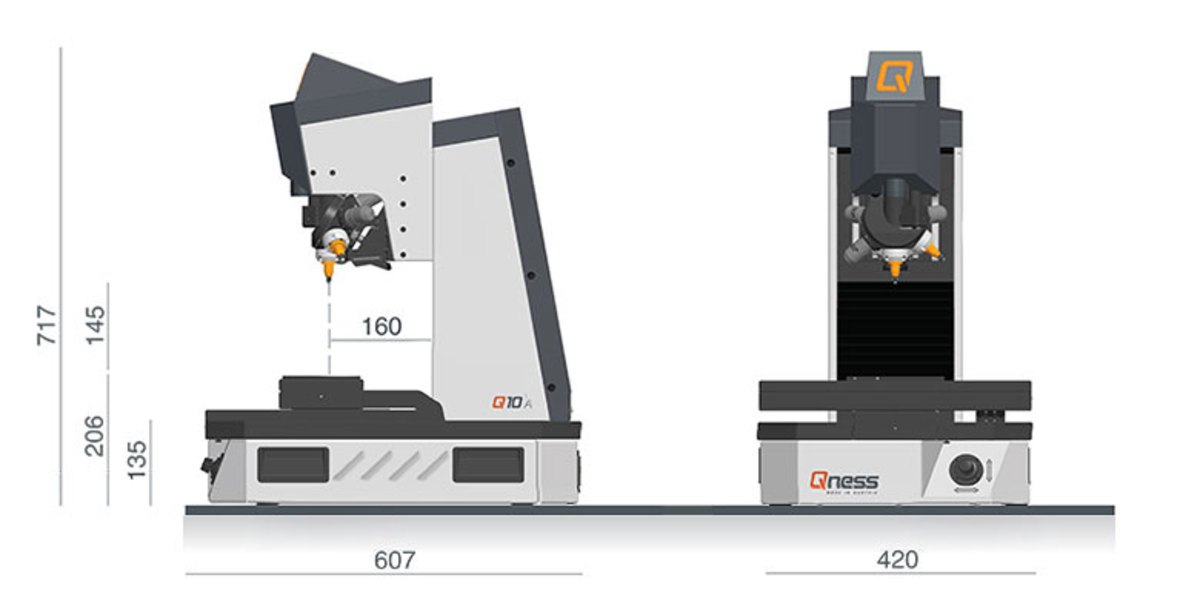

Q10/30/60 A/A+ VARIANTTECHNICAL DATA

| Test force range | Q10A / Q10A+: 50 g - 10 kg (0.49 - 98.1 N) Q30A / Q30A+: 100 g - 31.25 kg (0.98 - 306.6 N) Q60A / Q60A+: 200 g - 62.5 kg (1.96 - 613.1 N) |

| Test force range with extension | Q10A / Q10A+: 0.25 g - 10 kg (0.00245 - 98.1 N) Q30A / Q30A+: 0.25 g - 31.25 kg (0.00245 - 306.6 N) Q60A / Q60A+: 0.25 g - 62.5 kg (0.00245 - 613.1 N) |

| Tool changer | 6-fold, motorized |

| Software | Qpix Control2 |

| Sample image camera | Q10A / Q30A / Q60A: No Q10A+ / Q30A+ / Q60A+: Yes |

| Camera system | Q10A / Q30A / Q60A: 18 MP color camera Q10A+ / Q30A+ / Q60A+: 2 x 18 MP color camera |

| Traverse path X/Y/Z | X 150 / Y 150 / Z 145 mm |

| Weight of basic machine | 58 kg |

| Data interface | 1x USB3.0: Interface PC hardness tester |

| Max. workpiece weight | 50 kg |

| Power supply | 230~1/N/PE, 110~1/N/PE |

| Max. power consumption | ~200 W |

Accessories and Options |

|

| General | Lenses (2.5x, 4x, 10x, 20x, 40x, 65x, 100x) Penetrators (Vickers, Knoop, Brinell) |

| Sample holder | 1-fold, 4-fold (Ø 30 / 40 / 50 mm), 8-fold (Ø 30 / 40 mm) |

| Cross anvil | X 300 / Y 150 mm |